Stainless Steel Shot

Sandblasting High Strength 0.3 0.5 0.6 0.8mm 401 430 304 Stainless Steel Shot

Description of Sandblasting High Strength 0.3 0.5 0.6 0.8mm 401 430 304 Stainless Steel Shot

Steel Shot is a spherical pellet made by special heat treatment of special material, which melts high quality steel and then sprays it with high pressure water to form molten steel into fine particles. The formed pellet is reheated to purify Homogenized, then quenched. Quenched pellets are dried and reheated in a furnace to achieve a suitable hardness. Temper-treated steel pellets are classified by mechanical screen into different grades according to SAE standards for shot peening equipment .

Excellent heat treatment control process gives the steel ball the best flexibility and fatigue resistance, different particle size and hardness of steel shot for different processes, such as is widely used in large quantities and heavy parts or materials such as shot peening.

Steel shots are widely used for descaling and descaling pre-painted steel workpieces, in which case centrifugal shot blasting equipment is often used. Ball shape and hardness of the small steel balls will not produce greater wear and tear on the device.

Steel balls are also widely used in sand casting.

When used with the right equipment, steel balls are the best abrasive for surface cleaning because they are durable.

Details Description of Sandblasting High Strength 0.3 0.5 0.6 0.8mm 401 430 304 Stainless Steel Shot

Name | Steel shot |  | ||

Chemical composition | carbon | 0.70-1.20% | ||

manganese | 0.35-1.20% | |||

silicon | 0.40-1.20% | |||

sulfur | ≤0.05% | |||

phosphorus | ≤0.05% | |||

Average hardness | standard: 40-50HRC(377-509HV) | |||

special: 52-56HRC(543-620HV) | ||||

special: 56-60HRC(620-713HV) | ||||

Max. hardness deviation | ±3.0HRC(±40HV) | |||

Ervin life | 2000-2800cycles | |||

Microstrycture | uniform tempered martensite, or tempered troostite with well distributed carbides | |||

Min. density(alcohol replace testing) | 7.2g/cm3 | |||

Application of Sandblasting High Strength 0.3 0.5 0.6 0.8mm 401 430 304 Stainless Steel Shot

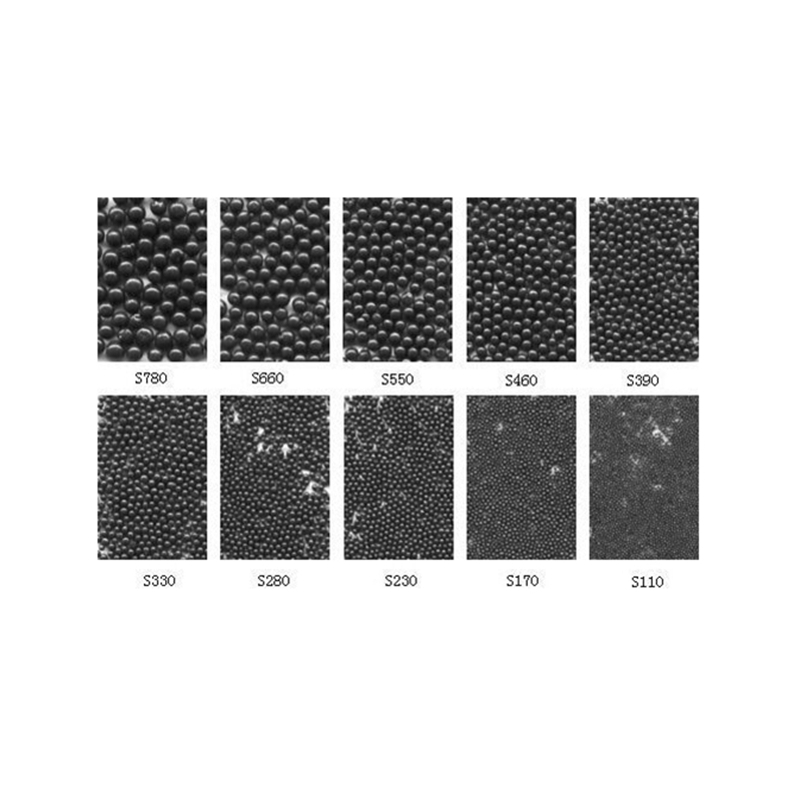

Model | Diameter | Application |

S-110 | 0.3--0.7mm | Shot peening stainless steel plate, thin steel plate and non-ferrous metals before painting process to increase elasticity and toughness. |

S-170 | ||

S-230 | ||

S-280 | 0.7--0.9mm | Blasting small cast iron, cast part, heat treatment piece, cast aluminum, cast steel plate and cast copper alloy before gold-plating process to increase elasticity and toughness. |

S-330 | 0.9mm--1.3mm | Knock-out, descaling, peening and shaping of small-to-medium cast iron, ductile iron, cast parts, heat treatment piece, steel plate, sections, steel pipe, structural parts, chain and non-ferrous metals. |

S-390 | ||

S-460 | 1.4mm--1.8mm | Knock-out, descaling, peening and shaping of medium-to-large cast iron, cast steel, forged piece, heat treatment piece, steel plate and pipe. |

S-550 | ||

S-660 | 1.9mm--2.6mm | Knock-out or descaling large cast iron, cast steel, iron pipe, forged piece and heat treatment piece. |

S-780 |

Packaging information of Sandblasting High Strength 0.3 0.5 0.6 0.8mm 401 430 304 Stainless Steel Shot

25kg /bag, 40 bags packed in a 1000kg bulk bag.

25kg /bag, 40 bags on a 1000kg pallet.

1000kg /jumbo bag.

Customized packing availble.

Delivery time of Sandblasting High Strength 0.3 0.5 0.6 0.8mm 401 430 304 Stainless Steel Shot

3-7 days for sample order;

5-25 days after receiving payment for mass order.

Established in 1976, DaLong Casting CO., LTD is a professional manufacturer and exporter for following:

-Abrasive Material

(corundum, fused alumina, garnet, copper slag, silicon carbide, dustless or soft sandblasting media, etc.)

-Refractory Material (bauxite, refractory brick/ball, castable material, bubble alumina, cenosphere, silicon carbide, etc.)

-Foundry Material(ceramsite, silica sand, lost foam/ V-Process casting coating, cast molding repair Paste)

-Filter Material (silica sand, ceramsite, ceramic sand, walnut shell, garnet, PAC, etc.)

-Chemical Products (Synthetic Cryolite, PAC, Alumina Oxide, etc.)

-Wear resistant Products (Grinding balls, crusher wearing parts, etc.)